As this technology advances, the concepts and the processes involved become easier to understand as fairly simplistic.

At it’s most basic, you might imagine it as a single drop of material that can adhere to the next as it drops one close, and/or passes by over head.

Advancements in CAD and computer technology combine design and manufacture.

Still thinking small, it becomes easier still to see how many different materials and material types and processes might be used.

It’s high cost effectiveness, has helped to enable it’s rapid evolution.

Observations of this technologies development indicate a very high potential for growth in domestic markets.

***BECAUSE this technology virtually bypass many areas of materials manufacturing, any level of growth in the domestic markets will result in a measurable impact commercially as well.

***High potential for societal influence as well.

http://www.extremetech.com/extreme/133514-the-worlds-first-3d-printed-gun

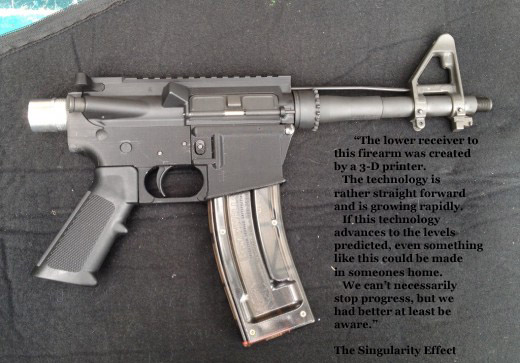

An American gunsmith has become the first person to construct and shoot a pistol partly made out of plastic, 3D-printed parts. The creator, user HaveBlue from the AR-15 forum, has reportedly fired 200 rounds with his part-plastic pistol without any sign of wear and tear.

HaveBlue’s custom creation is a .22-caliber pistol, formed from a 3D-printed AR-15 (M16) lower receiver, and a normal, commercial upper. In other words, the main body of the gun is plastic, while the chamber — where the bullets are actually struck — is solid metal.

The lower receiver was created using a fairly old school Stratasys 3D printer, using a normal plastic resin. HaveBlue estimates that it cost around $30 of resin to create the lower receiver, but “Makerbots and the other low cost printers exploding onto the market would bring the cost down to perhaps $10.” Commercial, off-the-shelf assault rifle lower receivers are a lot more expensive. If you want to print your own AR-15 lower receiver, HaveBlue has uploaded the schematic to Thingiverse.

HaveBlue tried to use the same lower receiver to make a full-blown .223 AR-15/M16 rifle, but it didn’t work. Funnily enough, he thinks the off-the-shelf parts are causing issues, rather than the 3D-printed part.

While this pistol obviously wasn’t created from scratch using a 3D printer, the interesting thing is that the lower receiver — in a legal sense at least — is what actually constitutes a firearm. Without a lower receiver, the gun would not work; thus, the receiver is the actual legally-controlled part.

In short, this means that people without gun licenses — or people who have had their licenses revoked — could print their own lower receiver and build a complete, off-the-books gun. What a chilling thought.

But hey, that’s the ambivalent nature of technology, the great enabler. In just the last few months, 3D printers have also been used to print organs, blood vessels, and drugs. In a few more years, when 3D printers move beyond plastic resins, who knows what we’ll be able to print.

Related articles

- Download, print, fire: gun rights initiative harnesses 3D technology (guardian.co.uk)

- 3D printer company seizes printer from wiki weaponsmith (wired.co.uk)